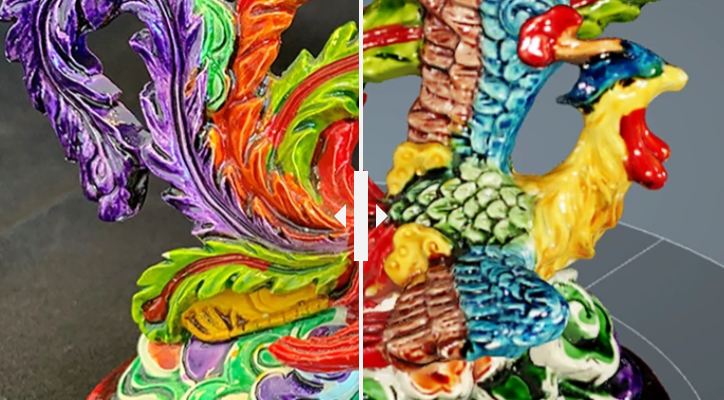

What does a 3D scan look like compared to the original object?

We show you the answer in this blog post. The rooster figurine we use is full of colors and intricate forms and is perfect for an example scan.

First, is a photo taken just before we scanned. In the background, you see the SOL 3D scanner placed inside its tent and set to near scanning position.

The first scanning pass is done with the rooster on its feet. The scanning happens inside the tent, so we look at the scanning through the software where this screen recording is from.

A scanning pass consists of 10 sweeps. The rooster is turned 1/10 of a round before each new sweep.

We also did a second scanning pass with the rooster on its right side to make sure the bottom parts were scanned as well.

After looking at the result we could see an area below the right wing that was not detected by the scanner in either of the scanning passes. So we added a third scanning pass with the rooster on its left side. Each scanning pass takes approximately 20 minutes depending on the computer.

Now the SOL Creator software meshes the 10 sweeps for each scanning pass and also meshes the scanning passes together. This is an automated process and we have done zero manual clean-up.

When we say the SOL scanner workflow is calibrate - scan - mesh - done we really mean it.

The scanning is now finished.

Note that it is always possible to add more scanning passes even after finishing.

Finished 3D scanning result

Below is your chance to look at the result in 3D.

You can change the layers - ie. set it to wireframe to see the triangulations and the scanning result without colors.